| Model | GD-12 YD-1 | GD-18 YD-6 | GD-24 YD-8 |

| Capacity(500ml/can/min) | 15-40 | 40-60 | 60-80 |

| Power(kw) | 0.55 | 0.75 | 0.87 |

| Overall dimensions(mm) | 810*800*1100 | 930*1050*1550 | 1800*1050*1750 |

| Weight(kg) | 480 | 550 | 650 |

| Model | GD12-4 | GD18-4 | GD24-6 | GD30-6 |

| Capacity (500ml/can/min) | 80-120 | 120-150 | 150-250 | 240-300 |

| Can apply to high(mm) | 65-190mm(Special height can be customized) | |||

| Filling temperature | 0-4ºC | |||

| Motor power(kw) | 5.5 | 6.5 | 7.8 | 8.5 |

| Overall dimensions(mm) | 2800*1600*2000 | 3000*1700*2000 | 3200*1800*2000 | 3500*1950*2000 |

| Wight(kg) | 3000 | 4000 | 4800 | 5200 |

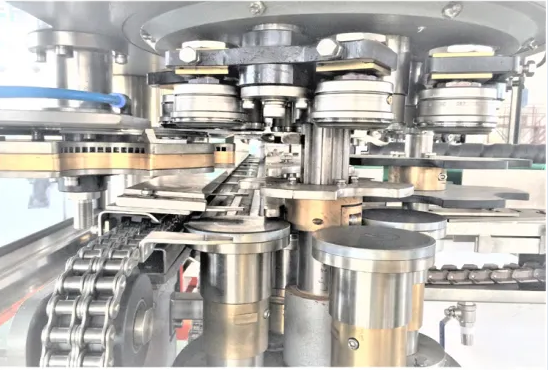

2.Sealing part and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping . All 304/316 stainless steel construction .No bottle no capping. Automatic stop when lack of bottle

2.Sealing part and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping . All 304/316 stainless steel construction .No bottle no capping. Automatic stop when lack of bottle

1.Can Depalletizer It can replace the manual can arrangement,increase production efficiency ,it is an indispensable ideal device for middle and large sized beverage plants ,plc programmable computer automatic controller ,photo-electricity switch,over travel-limit switch and pneumatic control ,etc ,use the famous brand from germany and japan and taiwan

1.Can Depalletizer It can replace the manual can arrangement,increase production efficiency ,it is an indispensable ideal device for middle and large sized beverage plants ,plc programmable computer automatic controller ,photo-electricity switch,over travel-limit switch and pneumatic control ,etc ,use the famous brand from germany and japan and taiwan

4. PE FILM SHRINK WRAPPING PACKAGE MACHINE Optional Equipment: 1) PE film shrink wrapping package machine 2) Half-Tray carton Shrink wrapping package machine 3) Carton package machine2. Can rising machine Inline can washing machine ,it will invert the can and rinsing the water ,the water can be recycled to save the water usage by the water collect .Use the famous brand from germany and japan and taiwan

4. PE FILM SHRINK WRAPPING PACKAGE MACHINE Optional Equipment: 1) PE film shrink wrapping package machine 2) Half-Tray carton Shrink wrapping package machine 3) Carton package machine2. Can rising machine Inline can washing machine ,it will invert the can and rinsing the water ,the water can be recycled to save the water usage by the water collect .Use the famous brand from germany and japan and taiwan

3.CARBONATED SOFT DRINK PRE-PROCESS SYSTEM 1 - High-shear emulsifying tank + Plate heat ex-changer 2 - Mixing tank 3 - Carbonated soft drink mixer+Refrigeration unit 4 - CIP cleaning system

3.CARBONATED SOFT DRINK PRE-PROCESS SYSTEM 1 - High-shear emulsifying tank + Plate heat ex-changer 2 - Mixing tank 3 - Carbonated soft drink mixer+Refrigeration unit 4 - CIP cleaning system